high quality standard according to RAL

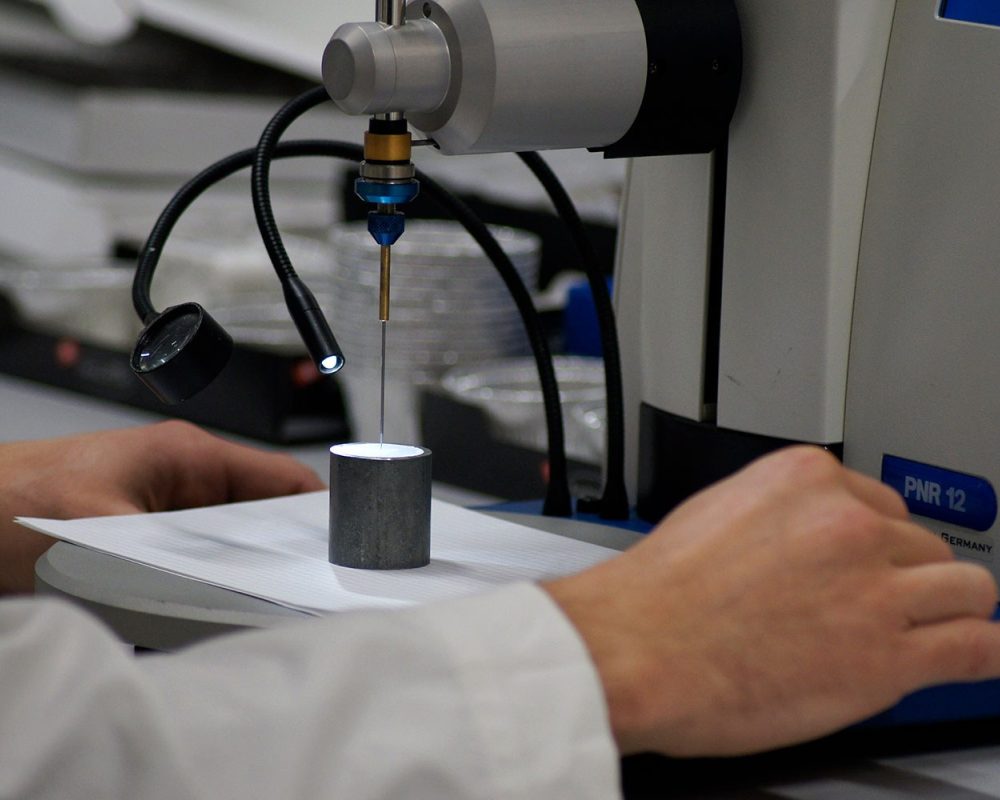

Candle quality and laboratory tests

Regular inspections and high standards guaranteed

CANDLE QUALITY WITH EXPERIENCE

Balthasar has many years of experience in testing and improving candle quality. Around 3000 comprehensive test orders are processed in our internal laboratory every year. For example, the candles are tested for the lowest possible soot behaviour, optimum flame size, correct colour, burning time and dripping behaviour. Torches, outdoor candles and torch oils also have to undergo inspection.

THE RAL QUALITY MARK AS A QUALITY STANDARD

Our requirements and quality standards are based on the guidelines of the RAL quality mark. This label stands for the outstanding quality and reliability of candles. Every batch of our in-house production as well as all delivery units from our candle suppliers are tested according to these criteria.

We are proud to say that our production has regularly passed the external RAL inspection by DEKRA in Stuttgart for many years and that we can officially award this quality mark to all of our own brands.

COLOUR ACCURACY AND CUSTOMER SERVICE

As we expand our product range, our laboratory team regularly develops new formulations for the colour mixtures, which are then implemented during production. This is the only way to ensure a colour-accurate end result.

In the event of customer complaints and queries, we are able to act rapidly internally, check the relevant batch again and react if necessary.

It is important to us to make our customers aware that even our high-quality and reliable candles should only be burnt under supervision. (Flame = open fire, therefore always under supervision.)